Imikhiqizo

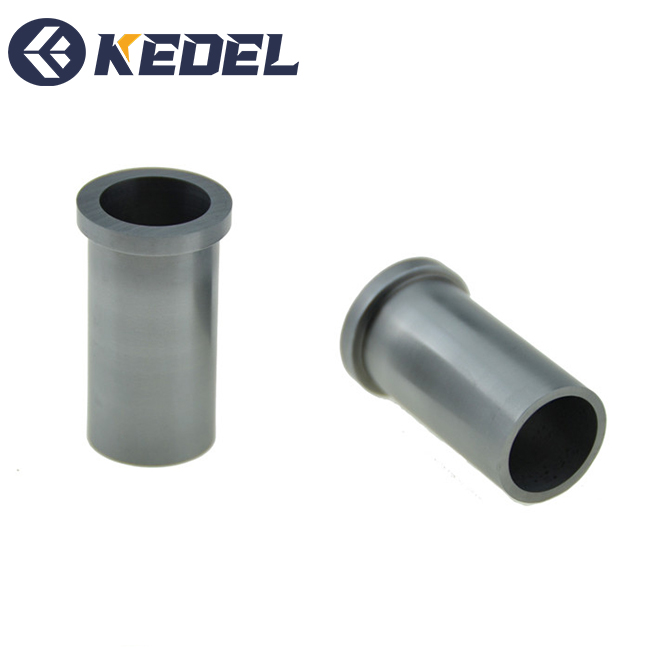

I-Anti Corrosion Tungsten Carbide Solid YG1C I-Threaded Drill Bushings

Isingeniso Somkhiqizo

I-Tungsten carbide bushing isethwe yi-virgin tungsten carbide material. Ibonisa ubulukhuni obuphezulu namandla okugoba. Lokho kunokusebenza okuphezulu ekumelaneni nokuhuzuka nokugqwala, okusetshenziswa kabanzi ezimbonini eziningi.

Ukuze isetshenziswe kabanzi. I-Tungsten carbide bushing ivame ukwenziwa ngokunemba okuphezulu, futhi ngenxa yokuqeda kwayo okuphelele, ubukhulu obunembe, ukuqina kanye nokumelana nokugqwala. Lezi zaziswa kakhulu ngamakhasimende emakethe ye-domistic kanye naphakathi.

Ngaphezu kwalokho, ihluke ezinhlobonhlobo zemvelo yohlelo lokusebenza. Kunezinhlobo eziningana ze-Tungsten carbide bushing. Imininingwane eminingi yenziwe ngokwezifiso. Ithuluzi le-Kedel lisekelwe ulwazi lwemboni ecebile nolwazi lokukhiqiza lwe-Tungsten carbide bushing ehlukahlukene. Lokhu kungakhiqiza i-tungsten carbide bushing ehlukahlukene ngokusekelwe kumklamo othize.

Izici Zomkhiqizo

1. Sebenzisa impahla eluhlaza ye-tungsten carbide engu-100%.

2. Izakhiwo zamakhemikhali ezizinzile

3. Ukusebenza okuhle kakhulu nokumelana nokugqokwa / ukugqwala okuhle

4. I-HIP sintering, ukubumbana okuhle

5. Izikhala, ukunemba okuphezulu kwemishini / ukunemba

6. OEM osayizi egcizelele ayatholakala

7. Isipho sefekthri

8. Ukuhlolwa kwekhwalithi yemikhiqizo eqinile

Imininingwane yokudweba

Ithebula lezinto ezibonakalayo

| Ibanga | ISO | Ukucaciswa | Ukusetshenziswa kwe-tungsten carbide | ||

| Ukuminyana | TRS | Ukuqina | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Ifanelekele ukwenziwa kwensimbi epholile epholile, i-alloy cast iron, i-refractory steel ne-alloy steel. Futhi Ufanelekele ukwenziwa kwensimbi evamile. |

| YG06 | K20 | 14.7-15. 1 | ≥1670 | ≥89.5 | Ifanelekele ukuqeda imishini kanye ne-semi-finish machining yensimbi ekhonjiwe, insimbi engeyona insimbi, i-alloy nezinto ezingahlanganisiwe. Futhi ifanelekele ukudweba ngocingo ngensimbi nensimbi engeyona i-ferrous, i-drill kagesi yokusebenzisa i-geology kanye ne-steel drill njll. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Ifanelekele ukukhanda insimbi ewugqinsi, insimbi engeyona insimbi, izinto ezingezona ezensimbi, ukudweba kwensimbi, insimbi engeyona ayoni namapayipi, ukubhola okuhlukahlukene okusetshenziselwa ukusetshenziswa komhlaba, amathuluzi okukhiqiza umshini kanye nezingxenye zokugqoka. |

| YG09 | I-K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | Ifanelekele ukusetshenzwa kanzima kwesivinini esiphansi, ingxube ye-titanium yokugaya kanye nengxubevange ye-refractory, ikakhulukazi ithuluzi lokusika kanye nephini likasilika. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Ifanelekela ukubumba izimbobo zokubhola i-rock-duty esindayo: izingcezu ezikhiphekayo ezisetshenziselwa ukubhoboza imbobo ejulile, i-rock drill trolley njll. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | Ifanelekele ukumba amatshe aqinile, amabha ensimbi anezilinganiso zokuminyanisa okuphezulu, umdwebo wamapayipi, amathuluzi okubhoboza, ikhabethe eliwumgogodla lezibumbi ezizenzakalelayo ze-powder metallurgy njll. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | Ifanelekele ukwenza ama-dies anomthelela ophansi njengokubhoboza izingxenye zewashi, amagobolondo ebhethri, ama-screw caps amancane njll. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | Ifanelekele ukwenza isikhunta sesihloko esibandayo, isitembu esibandayo nokucindezela okubandayo okusetshenziselwa ukukhiqiza izingxenye ezijwayelekile, ama-bearings njll. | |