Imikhiqizo

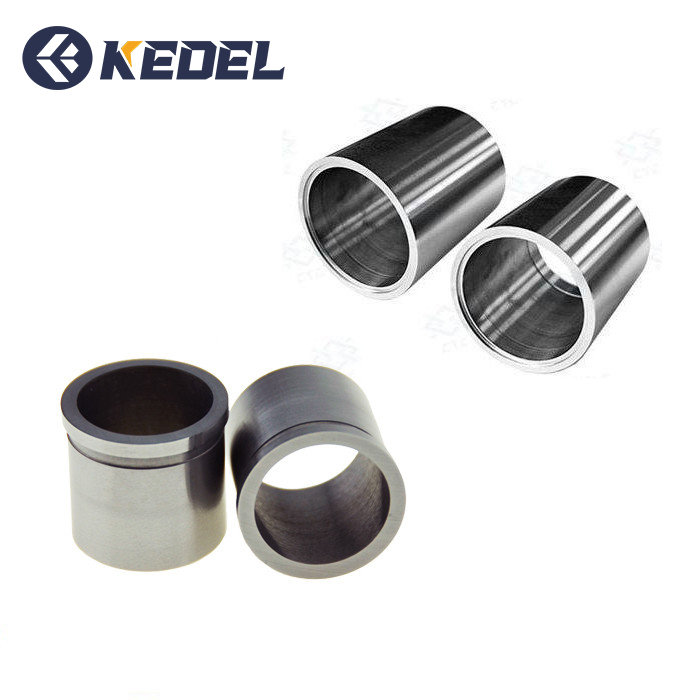

I-Cemented Tungsten Carbide Sleeves Bushings Yenkundla Yamafutha e-Submersibe

Isingeniso Somkhiqizo

Izicelo zemikhono ye-tungsten carbide zibanzi, okuyithuluzi lokuvikela isigaba sezingxenye. Kusemsebenzini wangempela kanye nendima nenjongo yemvelo yayo yesicelo inobudlelwano obukhulu.

Izicelo ze-valve, ama-bushings afakwe ku-valve stem cap trap, ukuze kuncishiswe ukuvuza kwe-valve, ukuvala; ukufaka izicelo, ukusetshenziswa kwehlathi ukunciphisa ukuguga phakathi kokuthwala kanye nesihlalo se-shaft, gwema igebe phakathi kwe-shaft kanye nokwanda kwembobo nokunye.

Ukukhiqizwa komkhono we-tungsten carbide kanye nokucutshungulwa kokuqina okuphezulu, kungamelana nomthwalo omude, ngokuzinza kwamakhemikhali aphezulu, i-alkali, utshwala, i-ether, ama-hydrocarbon, i-asidi, uwoyela, okokuhlanza, amanzi (amanzi olwandle), futhi ayinalo iphunga, izici ezingezona ezinobuthi, ezinganambitheki, ezingagqwali, ezisetshenziswa kakhulu embonini ye-petrochemical for Submerged Oil Pump, Pumpluc Pump, Pumpluc Pump, Pumpluc Pump.

izinzuzo

1, 100% impahla eluhlaza:

Ama-Bush akhiqizwa ngezinto zokusetshenziswa ezihlanzekile, ezinezici zempilo ende yokusebenza nokusebenza okuzinzile.

2, Ukuhamba:

Ama-Bushings acutshungulwa ngemishini enembayo ephezulu:Isikhungo semishini ye-CNC, umshini wokugaya, umshini wokugaya, umshini wokubhoboza, umshini wokugaya ovundlile, umshini wokugaya, iMetal Stamping, umshini wokusika we-CNC njll.

3, osayizi abaningi abatholakalayo:

Singanikeza ama-bushings anamasayizi ahlukene, isikhunta esiphelele kanye nesikhathi esifushane sokulethwa. Izinsuku ezingu-7-10 zamasampula .20-25 izinsuku zokusebenza zokukhiqiza okukhulu

4,Isiqiniseko sekhwalithi:

Amazinga Ekhwalithi Angeqiwe.Ama-bearings emikhono yethu yezihlahla aklanywe futhi akhiqizwa ngokuvumelana nezindinganiso eziqinile zekhwalithi ezilawula ukukhethwa kwempahla, umshini, ukuqedwa kwendawo, ukuhlolwa nokupakishwa.

Bonisa

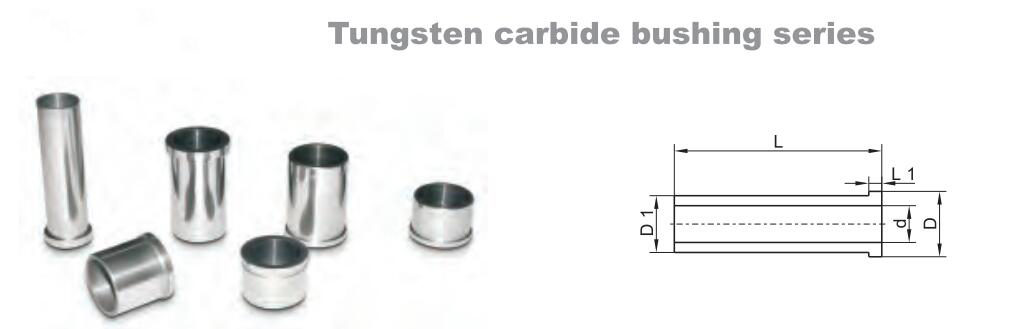

Imininingwane yokudweba

Ithebula lezinto ezibonakalayo

| Ibanga | ISO | Ukucaciswa | Ukusetshenziswa kwe-tungsten carbide | ||

| Ukuminyana | TRS | Ukuqina | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Ifanelekele ukwenziwa kwensimbi epholile epholile, i-alloy cast iron, i-refractory steel ne-alloy steel. Futhi Ufanelekele ukwenziwa kwensimbi evamile. |

| YG06 | K20 | 14.7-15. 1 | ≥1670 | ≥89.5 | Ifanelekele ukuqeda imishini kanye ne-semi-finish machining yensimbi ekhonjiwe, insimbi engeyona insimbi, i-alloy nezinto ezingahlanganisiwe. Futhi ifanelekele ukudweba ngocingo ngensimbi nensimbi engeyona i-ferrous, i-drill kagesi yokusebenzisa i-geology kanye ne-steel drill njll. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Ifanelekele ukukhanda insimbi ewugqinsi, insimbi engeyona insimbi, izinto ezingezona ezensimbi, ukudweba kwensimbi, insimbi engeyona ayoni namapayipi, ukubhola okuhlukahlukene okusetshenziselwa ukusetshenziswa komhlaba, amathuluzi okukhiqiza umshini kanye nezingxenye zokugqoka. |

| YG09 | I-K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | Ifanelekele ukusetshenzwa kanzima kwesivinini esiphansi, ingxube ye-titanium yokugaya kanye nengxubevange ye-refractory, ikakhulukazi ithuluzi lokusika kanye nephini likasilika. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Ifanelekela ukubumba izimbobo zokubhola i-rock-duty esindayo: izingcezu ezikhiphekayo ezisetshenziselwa ukubhoboza imbobo ejulile, i-rock drill trolley njll. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | Ifanelekele ukumba amatshe aqinile, amabha ensimbi anezilinganiso zokuminyanisa okuphezulu, umdwebo wamapayipi, amathuluzi okubhoboza, ikhabethe eliwumgogodla lezibumbi ezizenzakalelayo ze-powder metallurgy njll. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | Ifanelekele ukwenza ama-dies anomthelela ophansi njengokubhoboza izingxenye zewashi, amagobolondo ebhethri, ama-screw caps amancane njll. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | Ifanelekele ukwenza isikhunta sesihloko esibandayo, isitembu esibandayo nokucindezela okubandayo okusetshenziselwa ukukhiqiza izingxenye ezijwayelekile, ama-bearings njll. | |

Ithebula lobukhulu

| Imodeli No. | Ukucaciswa | I-OD(D:mm) | I-ID(D1:mm) | Imbobo(d:mm) | Ubude(L:mm) | Ubude besinyathelo(L1:mm) |

| I-KD-2001 | 01 | 16.41 | 14.05 | 12.70 | 25.40 | 1.00 |

| I-KD-2002 | 02 | 16.41 | 14.05 | 12.70 | 31.75 | 1.00 |

| I-KD-2003 | 03 | 22.04 | 18.86 | 15.75 | 31.75 | 3.18 |

| I-KD-2004 | 04 | 22.04 | 18.86 | 15.75 | 50.80 | 3.18 |

| KD-2005 | 05 | 16.00 | 13.90 | 10.31 | 76.20 | 3.18 |

| I-KD-2006 | 06 | 22.00 | 18.88 | 14.30 | 25.40 | 3.18 |

| I-KD-2007 | 07 | 24.00 | 21.00 | 16.00 | 75.00 | 3.00 |

| KD-2008 | 08 | 22.90 | 21.00 | 15.00 | 75.00 | 3.00 |

| I-KD-2009 | 09 | 19.50 | 16.90 | 12.70 | 50.00 | 4.00 |

| I-KD-2010 | 10 | 36.80 | 32.80 | 26.00 | 55.00 | 4.00 |