Imikhiqizo

I-High Precision Tungsten Carbide Epholishelwe Izinduku Ibha Eyindilinga

Isingeniso Somkhiqizo

Izinduku ze-Carbide zisetshenziselwa ikakhulukazi izinsimbi zokubhoboza, izinqamuli zokugaya kanye namawintshi. Ingabuye isetshenziselwe ukusika, ukunyathela kanye namathuluzi okulinganisa. Isetshenziselwa iphepha, ukupakisha, ukuphrinta, imboni non-ayoni metal processing. Ngaphezu kwalokho, isetshenziswa kabanzi ekwenzeni izinsimbi zensimbi ezinesivinini esikhulu, izisiki ze-carbide zokugaya, izisiki ze-carbide zikasimende, amathuluzi okusika e-NAS, izinqamu zezindiza, izingcezu ze-carbide zikasimende, izingcezu ze-milling cutter core, insimbi enesivinini esikhulu, abasiki be-taperd milling, abasiki be-metric milling, abasiki be-micro end milling, umshayeli we-hinge,ifayela le-carbide rotary, ithuluzi le-carbide elinosimende, njll.

Imininingwane Yomkhiqizo

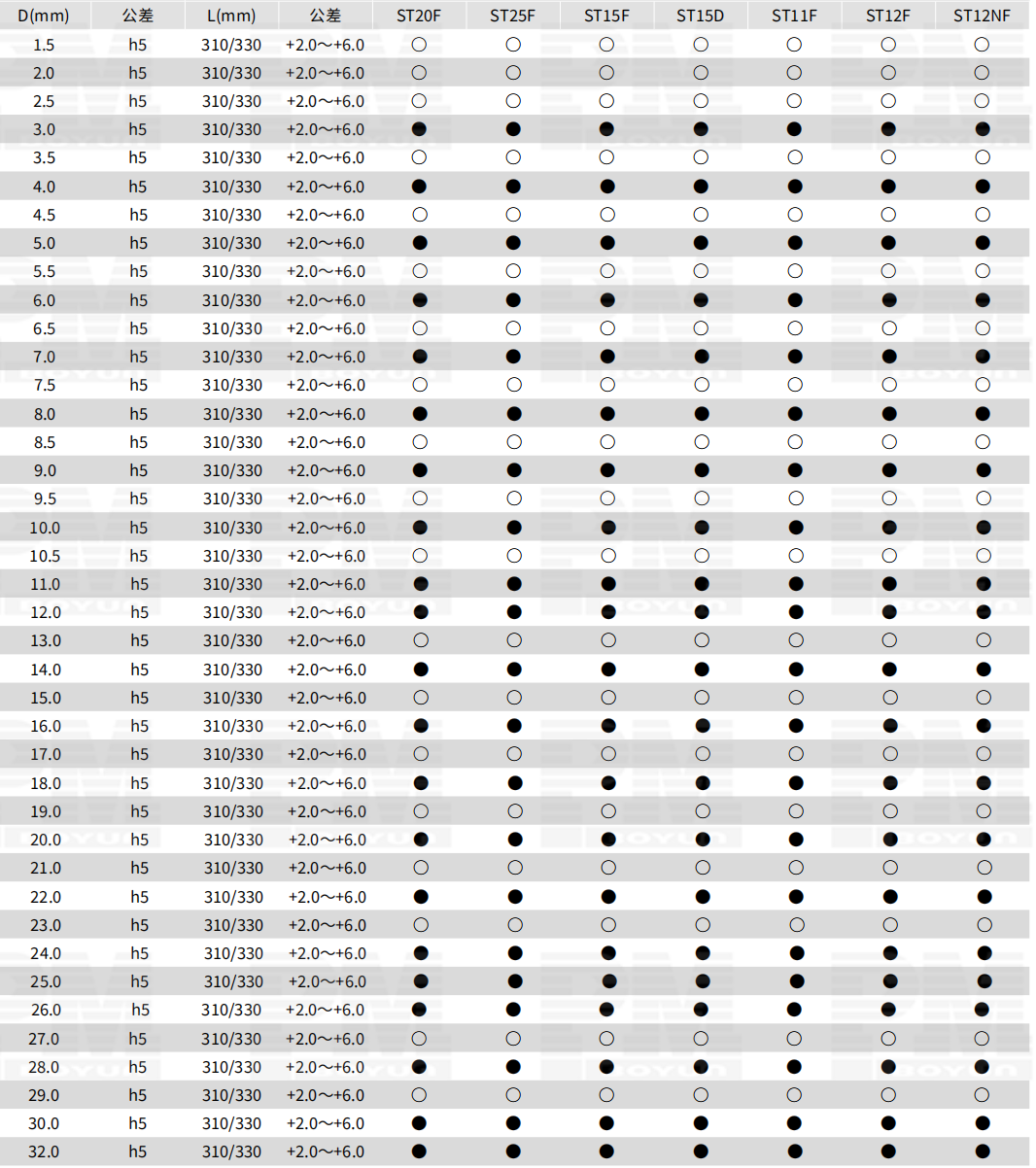

Osayizi Abakhonjiwe

Ishadi Lebanga Lezinto

| Isingeniso seBanga ku-Carbide Rods | |||||||

| Ibanga | Co % | WC usayizi wokusanhlamvu | HRA | HV | Ukuminyana (g/cm³) | Amandla okugoba (MPa) | Ukuqina kokuphuka (MNm-3/2) |

| I-KT10F | 6 | I-Submicron | 92.9 | 1840 | 14.8 | 3800 | 10 |

| I-KT10UF | 6 | kuhle kakhulu | 93.8 | 2040 | 14.7 | 3200 | 9 |

| I-KT10NF | 6 | i-nanometer | 94.5 | 2180 | 14.6 | 4000 | 9 |

| I-KT10C | 7 | Kuhle | 90.7 | 1480 | 14.7 | 3800 | 12 |

| I-KT11F | 8 | I-Submicron | 92.3 | 1720 | 14.6 | 4100 | 10 |

| I-KT11UF | 8 | kuhle kakhulu | 93.5 | 1960 | 14.5 | 3000 | 9 |

| I-KT12F | 9 | kuhle kakhulu | 93.5 | 1960 | 14.4 | 4500 | 10 |

| I-KT12NF | 9 | i-nanometer | 94.2 | 2100 | 14.3 | 4800 | 9 |

| I-KT15D | 9 | I-Submicron | 91.2 | 1520 | 14.4 | 4000 | 13 |

| I-KT15F | 10 | I-Submicron | 92.0 | 1670 | 14.3 | 4000 | 11 |

| I-KT20F | 10 | I-Submicron | 91.7 | 1620 | 14.4 | 4300 | 11 |

| I-KT20D | 10 | I-Submicron | 92.0 | 1670 | 14.3 | 4500 | 11 |

| I-KT25F | 12 | kuhle kakhulu | 92.4 | 1740 | 14.1 | 5100 | 10 |

| I-KT25EF | 12 | kuhle kakhulu | 92.2 | 1700 | 14.1 | 4800 | 10 |

| I-KT25D | 12 | kuhle kakhulu | 91.5 | 1570 | 14.2 | 4200 | 13 |

| I-KT37NF | 15 | i-nanometer | 92.0 | 1670 | 13.8 | 4800 | 10 |