Imikhiqizo

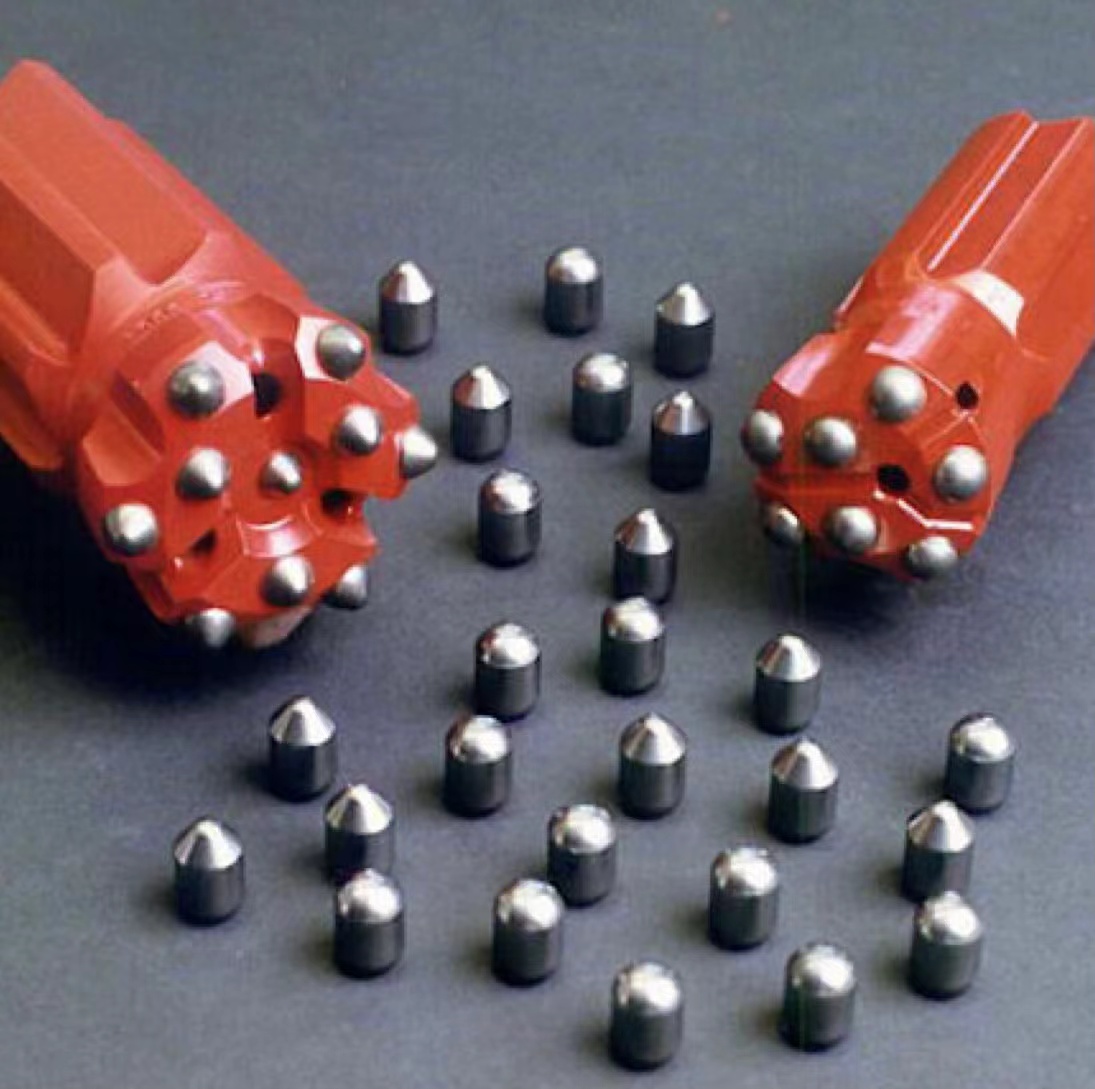

Izinkinobho ze-Tungsten Carbide zama-Rock Bits

Izinzuzo

1. Kwenziwe ngekhwalithi ephezulu kakhulu ye-carbide ngekhwalithi ezinzile futhi engaguquki.

2. Ukucubungula ngobuchwepheshe bakamuva bokukhiqiza i-HIP sintered ukuze kukhiqizwe ikhwalithi ephezulu.

3. Ukuhlolwa kwekhwalithi okuqinile kuhambisana nenqubo yokukhiqiza iyonke ukuze kuqinisekiswe ukuthi yonke iqoqo lomkhiqizo lihlangabezana nezinga lamakhasimende ngaphambi kokufakwa emakethe.

4. Uhlu olubanzi lwebanga le-tungsten carbide nosayizi wokukhetha.

5. Ukuthunyelwa okuqondile kwasefekthri kuqinisekisa isikhathi esifushane sokulethwa.

6. Siphinde sinikeze izeluleko ezinolwazi ukukusiza ukuthi ukhiqize umkhiqizo ongcono kakhulu ngenani eliphansi kakhulu.

7. Izinkinobho ze-carbide ezenziwe ngokwezifiso ziyatholakala, njll.

Inqubo Yokukhiqiza

Ukugaya--Ukuhlukanisa njengoba kudingeka--Ukugaya okumanzi--Omile--Granulation--Cindezela--Sinter--Inspection--Package

Imininingwane yokudweba

Ibanga Lereferensi

| Ibanga | Ukuminyana | TRS | Ubulukhuni HRA | Izinhlelo zokusebenza |

| g/cm3 | I-MPa | |||

| YG4C | 15.1 | 1800 | 90 | Isetshenziswa kakhulu njenge-drill yomthelela yokusika izinto ezithambile, eziphakathi neziqinile |

| YG6 | 14.95 | 1900 | 90.5 | Isetshenziswa njenge-electronic coal bit, i-coal pick, i-petroleum cone bit kanye ne-scraper ball tooth bit. |

| YG8 | 14.8 | 2200 | 89.5 | Isetshenziswa njenge-core drill, i-electric coal bit, i-coal pick, i-petroleum cone bit kanye ne-scraper ball tooth bit. |

| YG8C | 14.8 | 2400 | 88.5 | Isetshenziswa kakhulu njengezinyo lebhola le-bit encane naphakathi nendawo kanye nesihlahla esithwalayo sokubhoboza ukuhlola okujikelezayo. |

| YG11C | 14.4 | 2700 | 86.5 | Iningi lazo lisetshenziswa kumabhithi womthelela namazinyo ebhola asetshenziselwa ukusika izinto ezinobulukhuni obuphezulu kumabhithi ekhoni. |

| YG13C | 14.2 | 2850 | 86.5 | Isetshenziselwa kakhulu ukusika amazinyo ebhola wezinto eziqinile ezimaphakathi neziphezulu ekubholeni umthelela we-rotary. |

| YG15C | 14 | 3000 | 85.5 | Kuyithuluzi lokusika lokumba i-oil cone kanye nokubhola kwamatshe aqinile athambile namaphakathi. |