Imikhiqizo

I-Tungsten Solid Carbide Rods

Incazelo ye-Carbide Rods

Izinduku ze-Tungsten carbide zisetshenziswa kabanzi ekudaleni amathuluzi e-carbide aqinile e-premium, njengezigayo zokugcina, izinsimbi, izinsimbi zokuphinda, izisiki zokugaya, izitembu, namathuluzi okulinganisa ezimbonini ezihlukene.Ithuluzi le-Kedel likhiqiza izinduku ze-carbide ezisezingeni eliphezulu nezingaguquguquki ngamabanga ahlukahlukene ahlanganisa i-K20F, i-K25F, njll. Ukukhethwa okujwayelekile okubanzi kwezinduku ze-tungsten carbide ngobukhulu obuhlukahlukene kuyatholakala, futhi sinikezela ngezinsizakalo zokwenza ngokwezifiso ngokuya ngezidingo zakho. Njengomkhiqizi we-ISO, i-Kedeltool isebenzisa izinto ezisezingeni eliphezulu ukuze iqinisekise ikhwalithi nokusebenza kwezinduku zethu ze-carbide. Ngokuhlola ikhwalithi eqinile, singaqinisekisa ikhwalithi engaguquki phakathi kwenqwaba ngayinye.

Izinhlobo ze-Kedel Carbide Rod

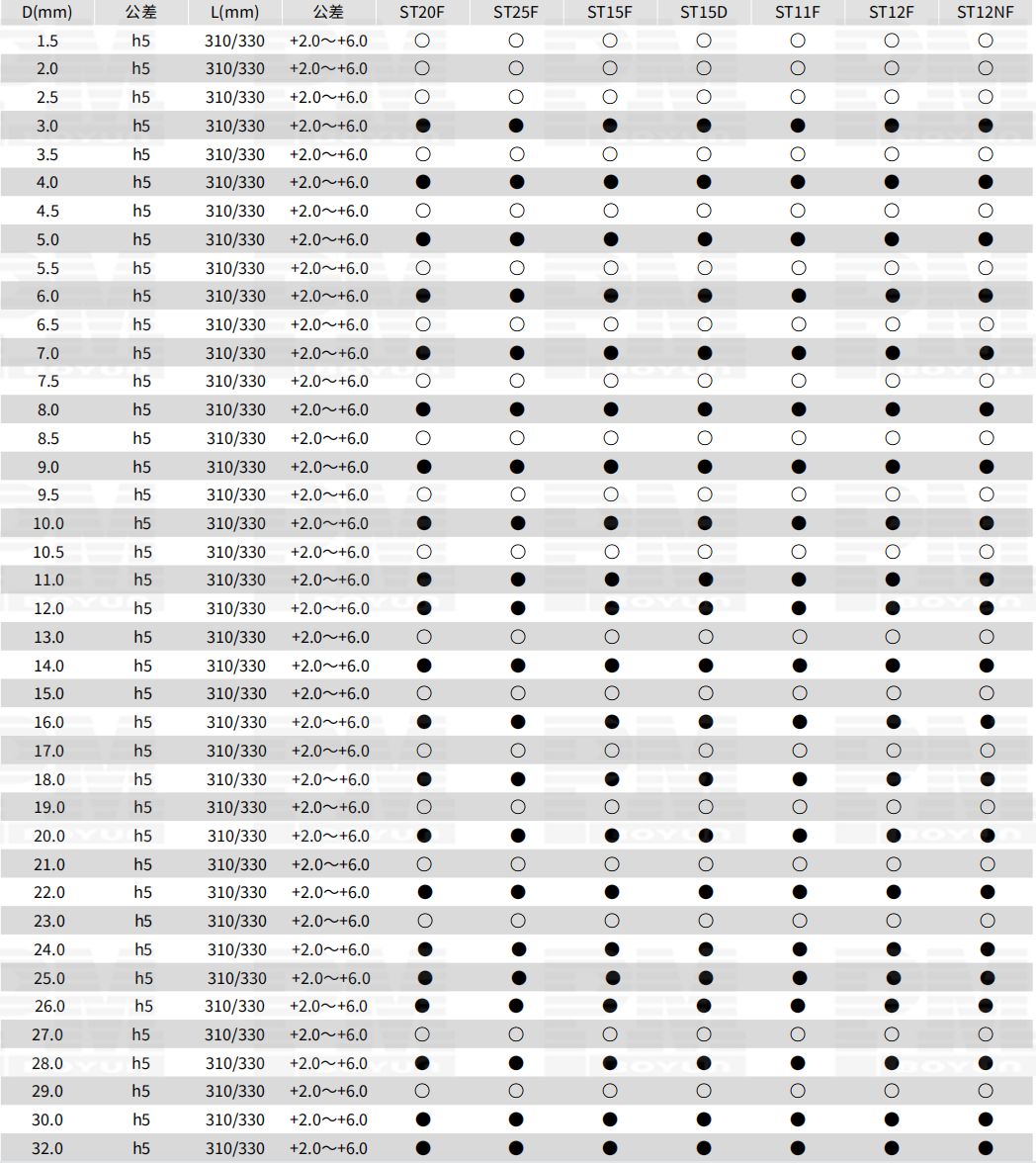

1. Izinduku zeCarbide eziqinile kumamethrikhi

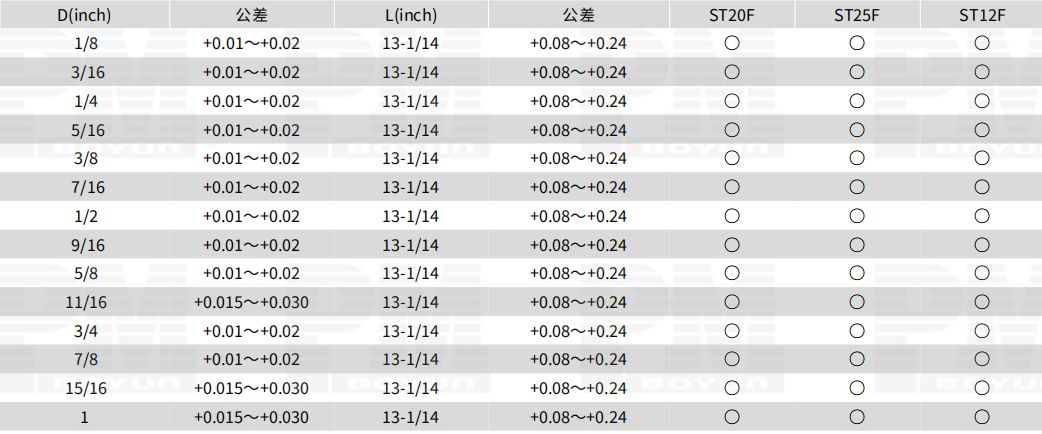

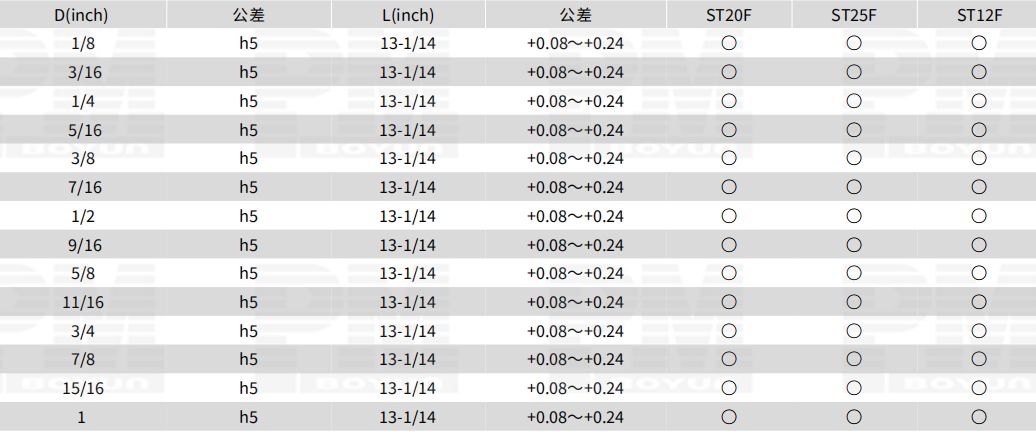

2. Izinduku Ze-Carbide Eziqinile Ngayintshi

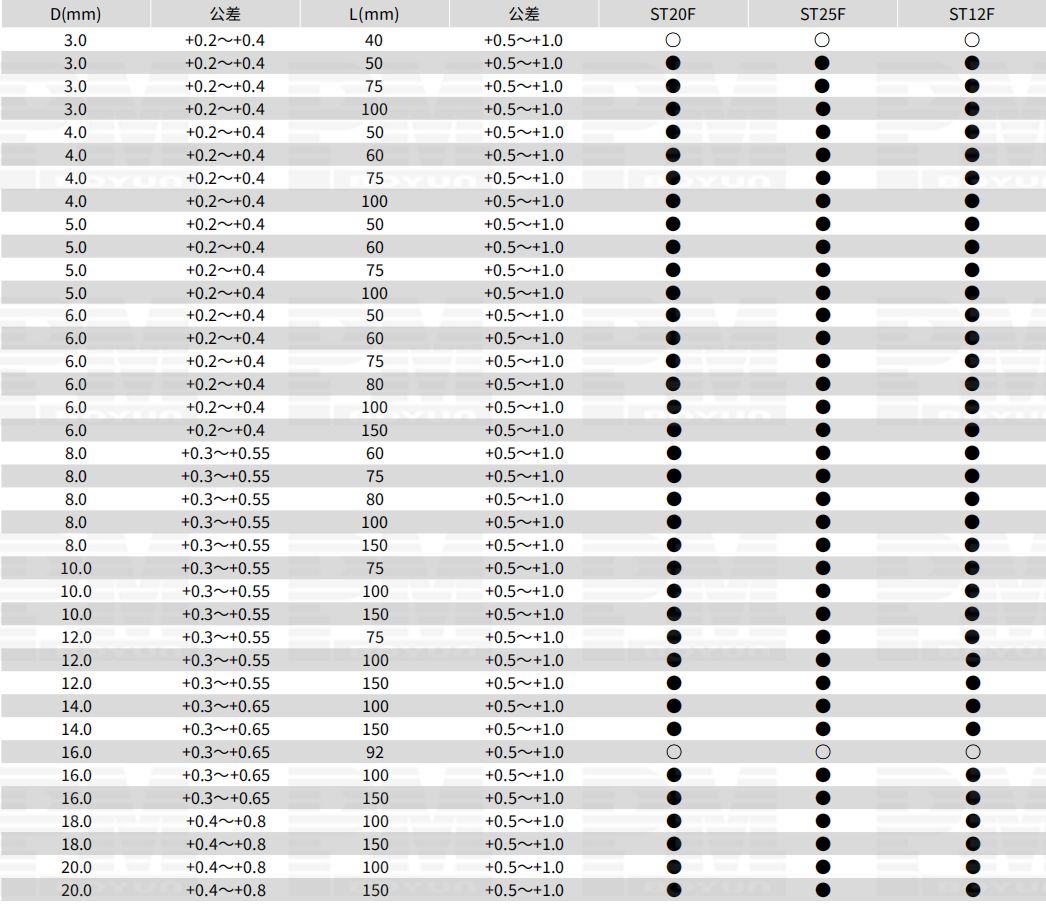

3. I-Drill Blanks (I-Chamfered)

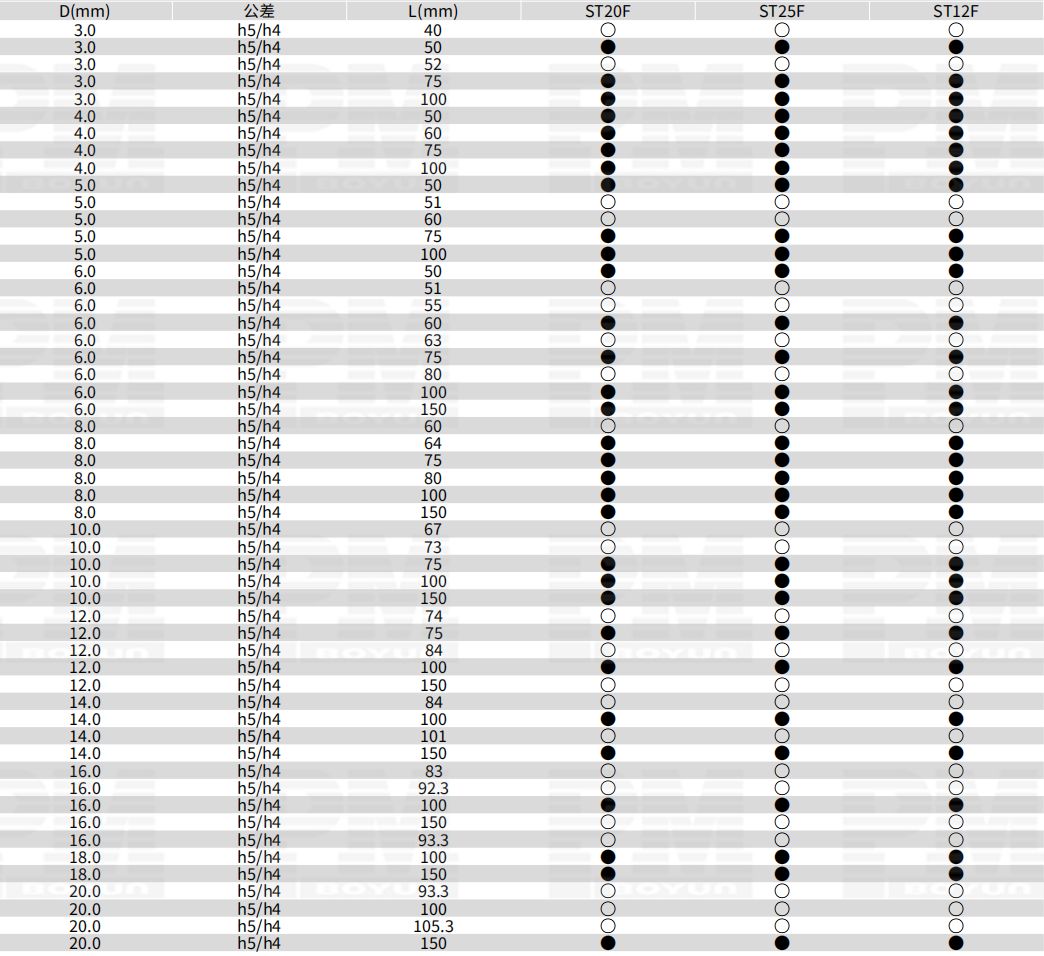

4. End Mill Blanks (Chamfered)

5. Izinduku Ze-Carbide ezineHole Epholile Emaphakathi Eqondile

6. Izinduku Ze-Carbide ezinezimbobo ezipholile ezimbili eziqondile

Izimpawu ze-Carbide Rod

1. Yenziwe ngekhwalithi ephezulu ye-tungsten carbide superfine powder

2. Imishini enembayo ene-10MPa HIP-Sinter isitofu sokukhiqiza esisezingeni.

3. Ubulukhuni obuphezulu namandla aphezulu

4. Izinzuzo ezikhethekile: Ubulukhuni obubomvu, ukumelana nokugqoka, i-elasticity modulus ephezulu, i-TRS, ukuqina kwamakhemikhali, ukumelana nomthelela, i-coefficient ephansi ye-dilatation, i-heat conduction kanye ne-electric conduction efanayo nensimbi.

5. Ubuchwepheshe obukhethekile: i-high pressure sintering ye-vacuum yokushisa ephezulu. Yehlisa i-porosity, yehlisa ukubumbana kanye nempahla eyimishini. Ibanga elihlukahlukene, izinhlobo namasayizi.

6. Ibanga elihlukile lereferensi yakho.

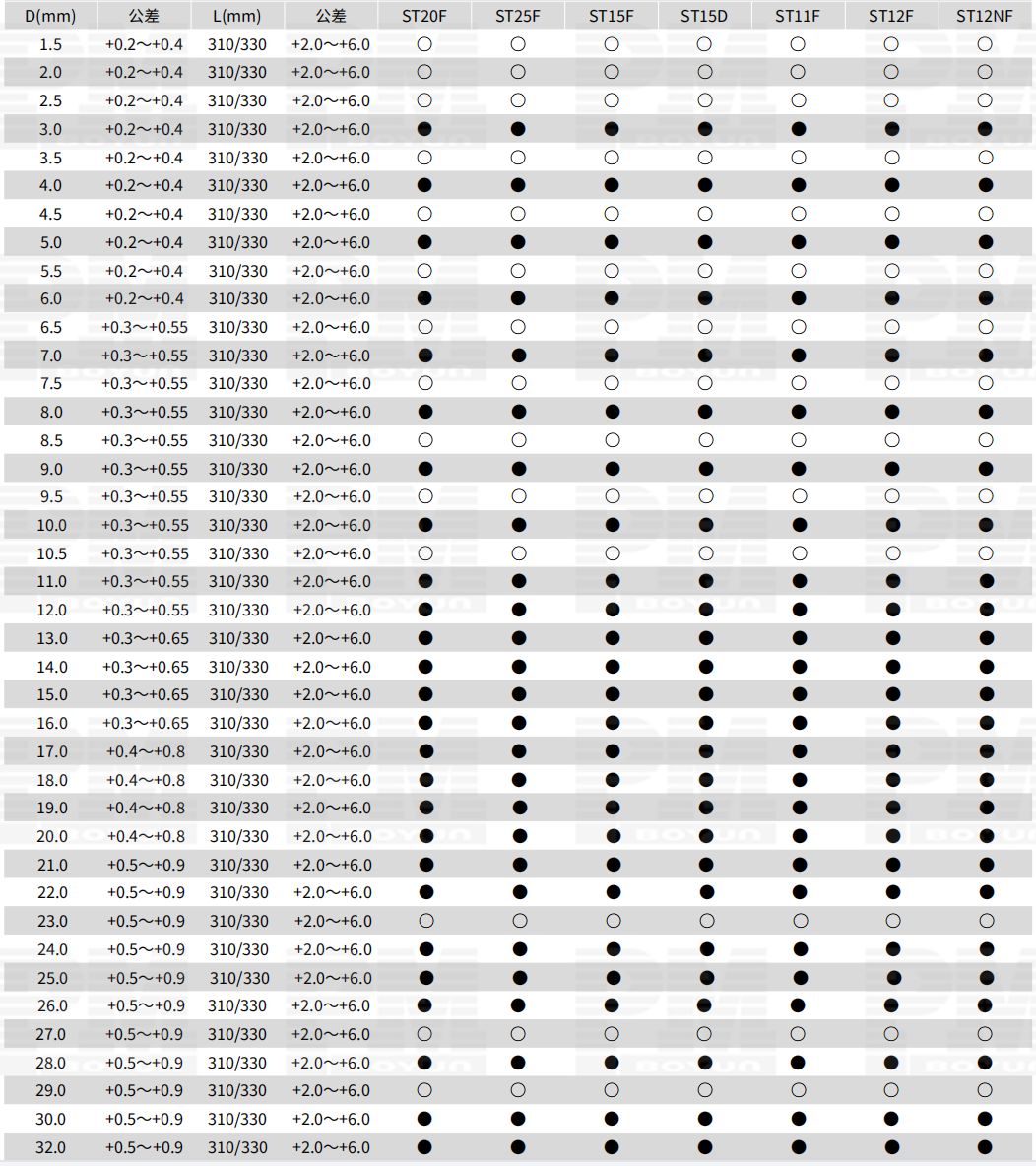

Osayizi Abavamile

Uhlu Lwebanga

| Isingeniso seBanga ku-Carbide Rods | |||||||

| Ibanga | Co % | WC usayizi wokusanhlamvu | HRA | HV | Ukuminyana (g/cm³) | Amandla okugoba (MPa) | Ukuqina kokuphuka (MNm-3/2) |

| I-KT10F | 6 | I-Submicron | 92.9 | 1840 | 14.8 | 3800 | 10 |

| I-KT10UF | 6 | kuhle kakhulu | 93.8 | 2040 | 14.7 | 3200 | 9 |

| I-KT10NF | 6 | i-nanometer | 94.5 | 2180 | 14.6 | 4000 | 9 |

| I-KT10C | 7 | Kuhle | 90.7 | 1480 | 14.7 | 3800 | 12 |

| I-KT11F | 8 | I-Submicron | 92.3 | 1720 | 14.6 | 4100 | 10 |

| I-KT11UF | 8 | kuhle kakhulu | 93.5 | 1960 | 14.5 | 3000 | 9 |

| I-KT12F | 9 | kuhle kakhulu | 93.5 | 1960 | 14.4 | 4500 | 10 |

| I-KT12NF | 9 | i-nanometer | 94.2 | 2100 | 14.3 | 4800 | 9 |

| I-KT15D | 9 | I-Submicron | 91.2 | 1520 | 14.4 | 4000 | 13 |

| I-KT15F | 10 | I-Submicron | 92.0 | 1670 | 14.3 | 4000 | 11 |

| I-KT20F | 10 | I-Submicron | 91.7 | 1620 | 14.4 | 4300 | 11 |

| I-KT20D | 10 | I-Submicron | 92.0 | 1670 | 14.3 | 4500 | 11 |

| I-KT25F | 12 | kuhle kakhulu | 92.4 | 1740 | 14.1 | 5100 | 10 |

| I-KT25EF | 12 | kuhle kakhulu | 92.2 | 1700 | 14.1 | 4800 | 10 |

| I-KT25D | 12 | kuhle kakhulu | 91.5 | 1570 | 14.2 | 4200 | 13 |

| I-KT37NF | 15 | i-nanometer | 92.0 | 1670 | 13.8 | 4800 | 10 |

Ukuze uthole ulwazi olwengeziwe (i-MOQ, intengo, ukulethwa) noma uma udinga izinsizakalo zokwenza ngokwezifiso, sicela ucele ikhotheshini.