Imikhiqizo

I-1/4” (6mm) i-Shank Tungsten carbide rotary burrs

Incazelo Yokukhiqiza

Ifayela elijikelezayo le-carbide elinosimende, elaziwa nangokuthi i-cemented carbide high-speed assorted milling cutter, i-cemented carbide die milling cutter, njll., isetshenziswa kanye nesigayo sikagesi esinesivinini esikhulu noma amathuluzi omoya.Ifayela elijikelezayo le-carbide elihlanganisiwe lisetshenziswa kabanzi emishinini, emotweni, emkhunjini, embonini yamakhemikhali, ekubazeni imisebenzi yezandla neminye imikhakha yezimboni.Ifayela elijikelezayo lengxubevange eqinile lingasetshenziselwa ukucubungula insimbi ewugqinsi, insimbi yokusansimbi, insimbi ye-carbon, insimbi yengxubevange, insimbi engagqwali, insimbi eqinile, ithusi ne-aluminium, njll. Njengoba ifayela elijikelezayo le-carbide likasimende liboshelwe ethuluzini elijikelezayo lesivinini esikhulu lenziwa ngesandla. ukulawula, ingcindezi kanye nesivinini sokuphakelayo kwefayela elijikelezayo le-carbide elisikiwe lincike empilweni yesevisi kanye nomthelela wokusika wethuluzi.

Izinzuzo

1. Ingakwazi ukucubungula insimbi eyinsimbi, insimbi ekhonjiwe, i-carbon steel, i-alloy steel, insimbi engagqwali, ithusi, i-aluminium nezinye izinsimbi, nemabula, i-jade, ithambo nezinye izinto ezingezona ezensimbi.Ukuqina kokucubungula kungafinyelela ku-HRA ≥ 85.

2. Ingakwazi ukufaka isibambo esikhundleni sesondo elincane lokugaya, futhi ayinakho ukungcola kothuli.

3. Ukusebenza kahle kokukhiqiza okuphezulu.Ukusebenza kahle kokucubungula kuphakeme ngokuphindwe kaningi kunefayela lesandla futhi cishe izikhathi eziyishumi ziphakeme kunesondo elincane lokugaya elinesibambo.

4. Ikhwalithi enhle yokucubungula nokuqeda okuphezulu.Ingakwazi ukucubungula izimbotshana zesikhunta ezinembe kakhulu.

5. Impilo ende yesevisi.Ukuqina kuphakeme ngokuphindwe ka-10 kunesisiki sensimbi esinesivinini esikhulu futhi siphakeme ngokuphindwe izikhathi ezingu-200 kunesosondo elincane lokugaya.

6. Kulula ukuyiqonda, kulula ukuyisebenzisa, iphephile futhi inokwethenjelwa.

7. Izindleko eziphelele zokucubungula zingancishiswa izikhathi eziningi.

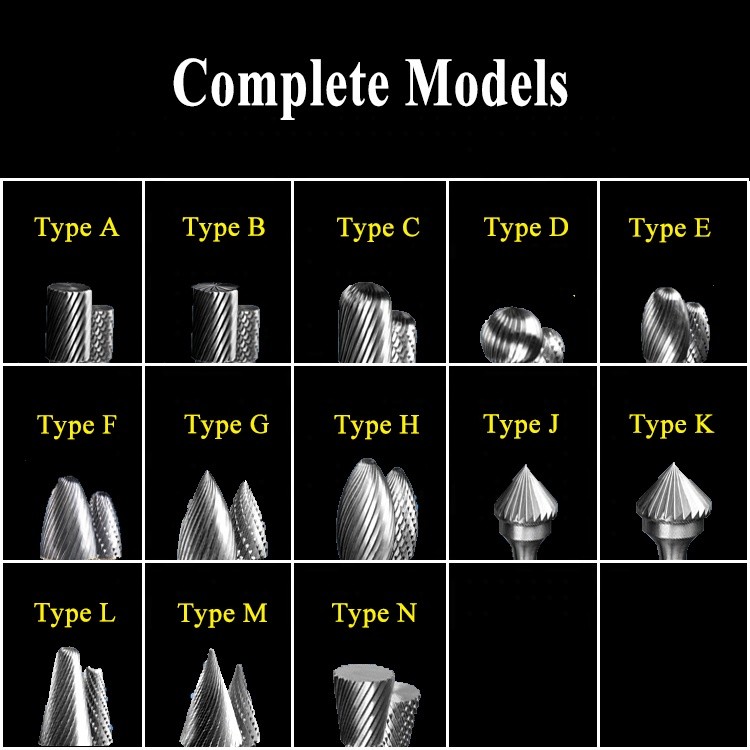

Izinhlobo Eziyinhloko

I-Shape A Cylindrical Plan End

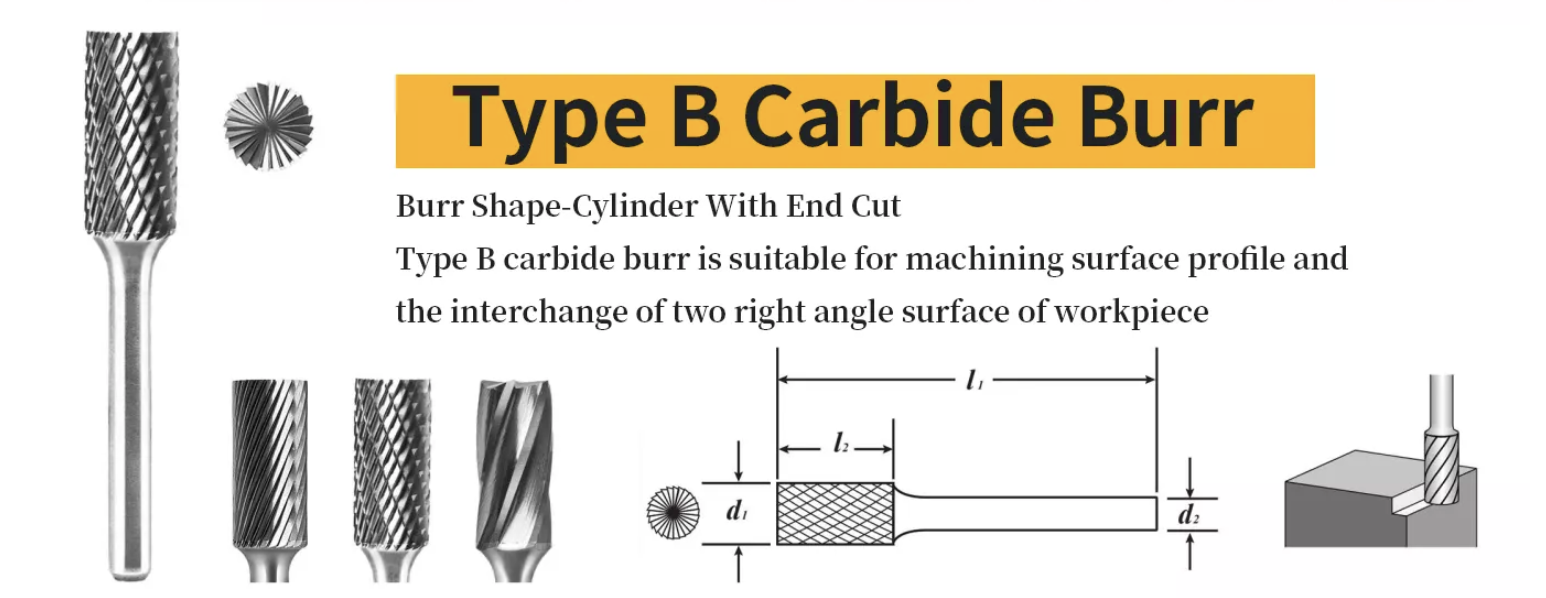

I-Shape B Cylindrical End Cut

Shape C Cylindrical Ball Nose

Shape D Ball Shape

Shape E Oval Shape

I-Shape F Tree Radius End

Umumo wesihlahla se-G Point

Shape H Flame Shape

Uzinki wokubala we-Shape J 60-degree

Uzinki owumumo ongu-K 90-degree countersink

I-Shape L Cone Radius End

Umumo Okhombe Ikhoni elingu-M

Umumo N Ikhoni Eguquliwe

Osayizi Abayinhloko

| Usayizi Wemethrikhi | ||||||

| I-Shank Diameter(mm) | I-Cutter Diameter(d1) | Ubude bokusika(l2) | I-Shank Diameter(d2) | Ubude Bebonke(L1) | Inombolo Yethuluzi. | Uhlobo |

| 6.0 | 6 | 16 | 6 | 50 | B60616 | okuqinile |

| 6 | 16 | 6 | 61 | B60616 | brazed | |

| 8 | 20 | 6 | 65 | B60820 | brazed | |

| 10 | 20 | 6 | 65 | B61020 | brazed | |

| 11 | 20 | 6 | 70 | B61125 | brazed | |

| 12 | 25 | 6 | 70 | B61225 | brazed | |

| 16 | 25 | 6 | 70 | B61625 | brazed | |

| 20 | 25 | 6 | 70 | B62025 | brazed | |

| 25 | 25 | 6 | 70 | B62525 | brazed | |