Imikhiqizo

I-6mm Shank Diameter Sika Kabili Umumo Wesihlahla Esinomumo Wokuphela Kwerediyasi I-Tungsten Rotary Carbide Burr

Izinzuzo ze-Kedel carbide burrs

1,Yenziwe nge-Solid tungsten carbide YG8 ephethwe ngokushisa ehlala izikhathi eziyi-8 zokusebenza Ihlala isikhathi eside kunethuluzi le-HSS

2, i-Kedel cabide cutting burrs yezesekeli zomshini wokufa- ilingana nezigayo eziningi ze-Rotary Die

3,Ihlala isikhathi eside: Yenziwe nge-tungsten carbide ephethwe ngokushisa obuqinile bungafinyelela ku-HRC70, ibukhali futhi iqinile

4, Okuguquguqukayo: Kusetshenziswa kakhulu ukwenza insimbi, ukwenza amathuluzi, ubunjiniyela bemodeli, ukubaza ukhuni, ukwenza ubucwebe, ukushisela, ukukhanda, ukuphonsa, ukukhipha, ukugaya, ukuthuthwa kwekhanda lesilinda nokuqopha

5,Ithagethi:Ifanele wonke amazinga wamakhono: lena ikhithi ebalulekile yabasebenza ngokhuni & abathanda abahlanza amashisela noma abasebenza ngensimbi njalo, kulula ukuyiqonda nokusebenzisa, ephephile futhi enokwethenjelwa.

6, Isivikelo: Ipakishwe ngekesi lepulasitiki ukuze ligcinwe futhi livikeleke

Incazelo Yomkhiqizo

| Ukukhiqiza | Intengo yefekthri, Isevisi ye-OEM yakho |

| Ibhrendi | KEDEL |

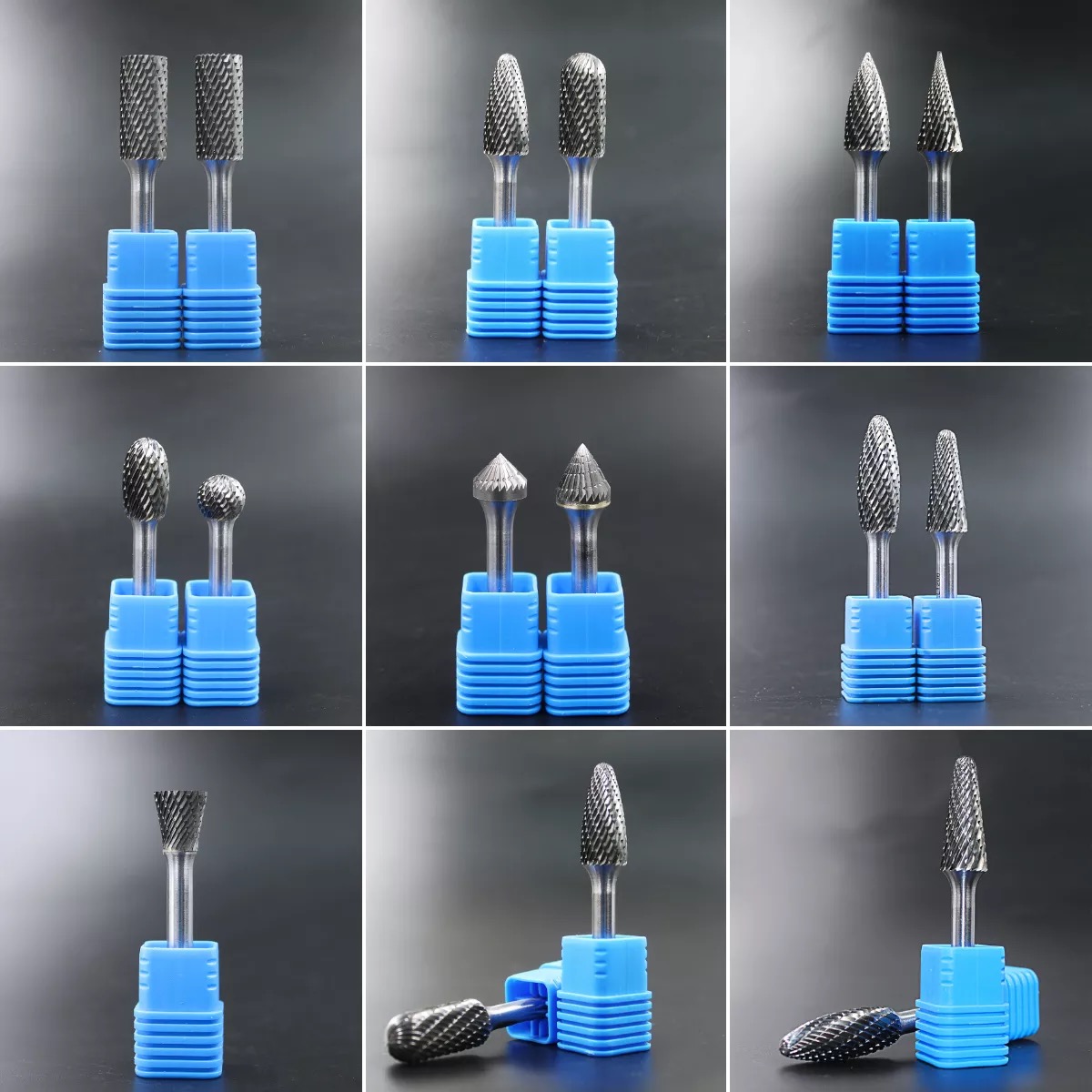

| Isimo Somsiki | A/B/C/D/E/F/G/H/J/K/L/M/N Uhlobo |

| Okubalulekile | 100% Tungsten steel Hard Carbide |

| Ububanzi bekhanda | 3mm 4mm 6mm 8mm 10mm 12mm 14mm 16mm |

| Ububanzi be-Shank | 1/2inch / 1/4inch/1/8inch |

| HRA | HRA 89-92.5 ubulukhuni |

| Ifanele | Ukubhoboza, Ukuhalela insimbi, ukuqopha, ukupholisha |

| Ngokwezifiso | OEM & ODM |

| I-KEDELTOOLS ikhiqiza uhla olubanzi lwamabhasi e-carbide ekhwalithi ephezulu namasaha we-bi-metal hole. Amabhasi e-KEDELTOOLS aletha ukusebenza okuphezulu kakhulu kokukhipha isitoko kuyo yonke impilo yawo yesevisi, enikeza imiphumela evelele ngesikhathi esincane. | |

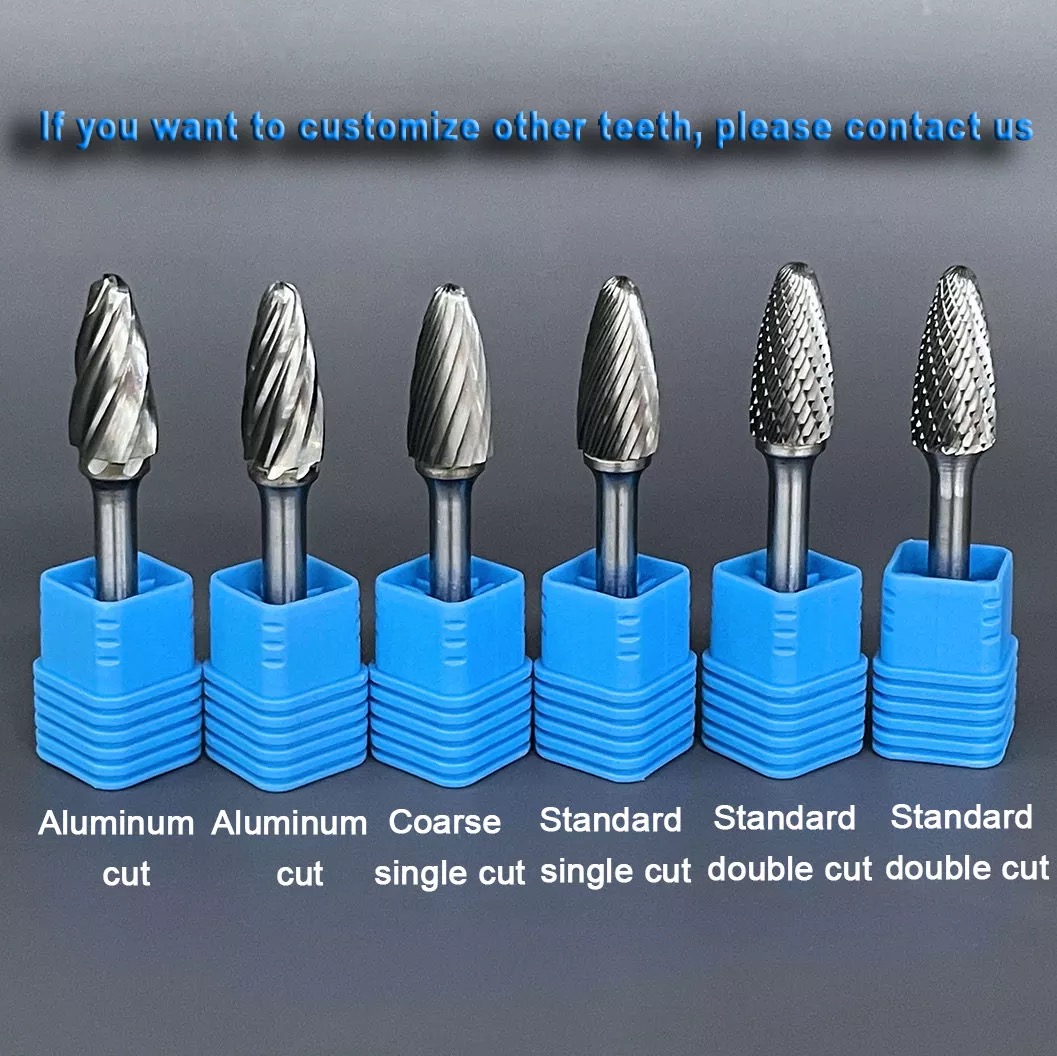

| I-Tungsten Carbide Conical Pointed Nose Rotary Burrs Use for Insimbi Yensimbi Eqinile I-aluminium Alloys Yethusi Ezinye izinsimbi ezingezona ayoni Insimbi eqinile engeyona insimbi Insimbi engagqwali (INOX) Ikesi eliqinile izinsimbi Insimbi, insimbi esakhiwe Izinsimbi eziqinile, ezifakwe ukushisa ngaphezu kuka-1,200 N/mm2 (ngaphezu kuka-38 HRC) Izinsimbi eziqinile, ezifakwe ukushisa ngaphezu kuka-1,200 N/mm2 (ngaphezulu kokungu-38 HRC) Izinsimbi eziqinile, ezifakwe ukushisa ngaphezu kuka-700 N/mm² (> 220 HB) Insimbi empunga/nodular cast (GG/GJL, GGG/GJS) Insimbi yokusansimbi I-Copper Ethambile yensimbi engeyona insimbi Ithusi Insimbi eqinile engeyona insimbi Insimbi ewugqinsi emnyama (GTS, GJMB) Insimbi ecijile ene-annealed Insimbi yensimbi, insimbi esakhiwe Izinsimbi ezingafika kokungu-1,200 N/mm² (< 38 HRC) Izinsimbi ezingafika kokungu-700 N/mm² (< 220 HB) Izinto zensimbi esakazwayo ezinobunzima obungaphezu kuka-54 HRC Insimbi eyi-Annealed cast iron Titanium Titanium alloys Insimbi exutshwe nensimbi emhlophe (GTW, GJMW) Ithuluzi lezinsimbi ze-Zinc | Iphethini yokusika: * I-DX: Sika kabili * C: I-Coarse Cut * M: I-Standard Single Cut * W: I-Aluminium Cut Single Cut * F: I-Fine Single Cut * Z: Cast I-Single Cut * MX: I-Standard Cross Gear Cut * ZX: Casting Cross Cut * L: Ukusika Kwedayimane * I-SX: I-Steel File Cross Cut * I-FX: I-Fine Tooth Cross Cut *CX: I-Coarse Cross Cut * I-WX: I-Aluminium Cut Cross Cut * Okunye Xhumana nathi |

| Ukucaciswa : * I-HRA: ≥ 85 * I-RPM Ephakanyisiwe:25000-50000, Max RPM 70000 * Iphakheji: Iphakeji ngayinye futhi ingenziwa ngezifiso * Ubuchwepheshe: I-100% I-Flat bottom yesiliva welding tungsten carbide burrs | Izici: * Isetshenziselwa ukucubungula zonke izinhlobo zensimbi (okuhlanganisa insimbi eqinile) kanye ne-nonmetal * Ukusebenza kahle okuphezulu kokukhiqiza, Kunganciphisa amandla okusebenza okulula ukuwasebenzisa. * Isetshenziswa kabanzi kumathuluzi womoya noma kagesi. |

Isicelo

Ingacutshungulwa ngensimbi eyinsimbi, insimbi ekhonjiwe, i-carbon steel, i-alloy steel, insimbi engagqwali, ithusi, i-aluminium nezinye izinsimbi, nemabula, i-jade, ithambo nezinye ezingezona ezensimbi. Icubungula ubulukhuni kufika ku-HRA85.

Inzuzo

1. Isipiliyoni seminyaka eyi-10.

2. 100% impahla entsha.

3. Yiba isikhathi eside.

4. Isevisi ye-OEM ne-ODM.

5. Yonke imigomo yokukhokha iyasekelwa.

6. Fast ukulethwa isikhathi & Ezokuthutha Elula

Imininingwane Yomkhiqizo