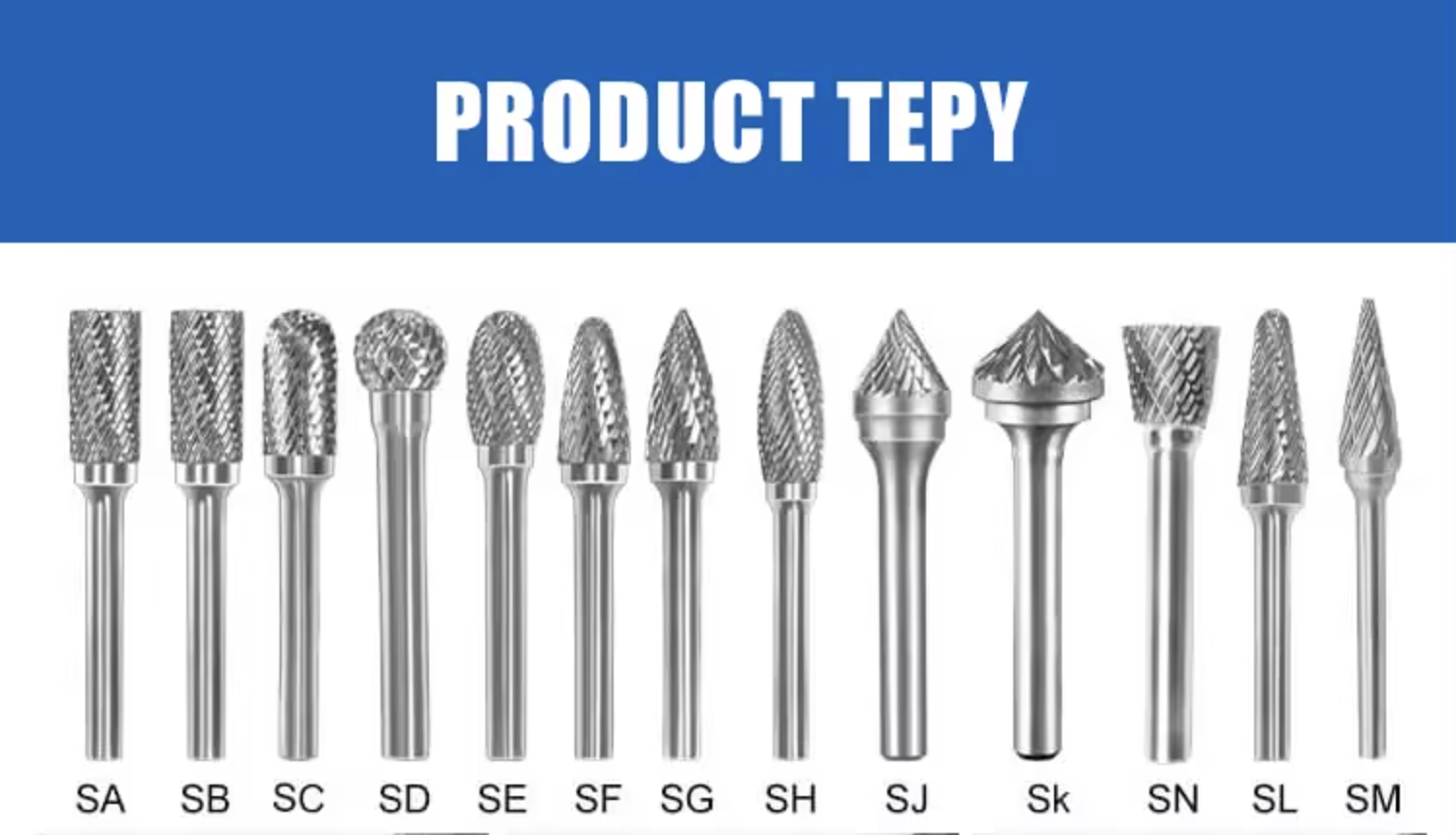

Amafayela e-Tungsten carbide rotary iyithuluzi elivamile lokucubungula insimbi, elitholakala ngezinhlobo eziningi, elisetshenziswa kabanzi ekucubunguleni kwemishini, ukulungiswa kwezimoto, i-aerospace kanye neminye imikhakha. Lesi sihloko sizokwethula ukusetshenziswa kwezinhlobo ezahlukene zamafayela ajikelezayo e-alloy, kanye nendima yawo kanye nenani emikhakheni ehlukahlukene.

Ukusetshenziswa kwamafayela e-steel carbide rotary ku-machining

Ama-burrs engxube yensimbi awuhlobo oluvame kakhulu futhi avame ukusetshenziselwa ukukhanda okunembayo kwezingxenye zensimbi. Emkhakheni wokwenza imishini, amafayela ajikelezayo ensimbi angasetshenziselwa ukunquma, ukushelela nokukhipha ama-burrs ezindaweni zensimbi ukuze kuqinisekiswe ukunemba kanye nekhwalithi ephezulu yezingxenye. Ukumelana nokugqokwa kwayo nokuqina kwayo kuyenza ibe ithuluzi elibalulekile ekwenzeni imishini.

Ukusetshenziswa kwamafayela we-tungsten carbide alloy rotary ekulungisweni kwezimoto

Amafayela we-Tungsten carbide alloy rotary anobulukhuni obuphakeme nokumelana nokugqoka futhi afanele ukucubungula izinto eziqinile. Emkhakheni wokulungiswa kwezimoto, amafayela we-tungsten carbide alloy rotary avame ukusetshenziselwa ukunquma izingxenye zenjini, amasondo amasondo nezinye izingxenye zensimbi. Bangakwazi ukususa ngokushesha ama-surface burrs, bathuthukise ukunemba nekhwalithi yezingxenye, futhi baqinisekise ukuphepha nokuthembeka kwezimoto.

Ukusetshenziswa kwamafayela we-titanium alloy rotary emkhakheni we-aerospace

Amafayela e-Titanium alloy rotary anokumelana nokugqwala okuhle kakhulu nokusebenza kwezinga lokushisa eliphezulu, futhi afanele ukucubungula izingxenye ze-titanium alloy. Emkhakheni we-aerospace, amafayela e-titanium alloy rotary avame ukusetshenziselwa ukunquma izingxenye zenjini yendiza, izingxenye zesakhiwo semikhumbi-mkhathi, njll., ezingasusa ngempumelelo amaphutha angaphezulu, zithuthukise ukunemba kanye nekhwalithi ephezulu yezingxenye, futhi kuqinisekiswe ukwethembeka nokuphepha kwemishini yasemkhathini.

Ukusetshenziswa kwamafayela e-rotary ensimbi engagqwali ekukhiqizeni idivayisi yezokwelapha

Amafayela ajikelezayo ensimbi engagqwali anokumelana nokugqwala okuhle kanye nenhlanzeko, futhi afanele ukucubungula nokukhiqizwa kwemishini yezokwelapha. Emkhakheni wokwenziwa kwemishini yezokwelapha, amafayela ajikelezayo ensimbi engenasici avame ukusetshenziselwa ukunquma amathuluzi okuhlinza, amathuluzi okufakelwa, njll., angaqinisekisa ukushelela nokunemba kwendawo yensimbi futhi aqinisekise ukuphepha nokuhlanzeka kwensiza yezokwelapha.

Amafayela e-rotary alloy alloy aqinisekisa ukunemba kanye nekhwalithi ephezulu yezingxenye ekusebenzeni kwemishini; amafayela we-tungsten carbide alloy rotary athuthukisa ukunemba nokuthembeka kwezingxenye ekunakekelweni kwezimoto; amafayela we-titanium alloy rotary aqinisekisa ikhwalithi yamadivayisi we-aerospace emkhakheni we-aerospace Ukuthembeka nokuphepha; insimbi engagqwali ingxubevange amafayela rotary aqinisekisa inhlanzeko nokuphepha izinsimbi ekukhiqizeni idivayisi yezokwelapha. Izinhlobo ezahlukene zamafayela ajikelezayo e-alloy zidlala indima ebalulekile emikhakheni yazo futhi zinikeza ukwesekwa okuqinile kokuthuthukiswa kwezimboni ezihlukahlukene.

Isikhathi sokuthumela: Feb-19-2024