Imikhiqizo

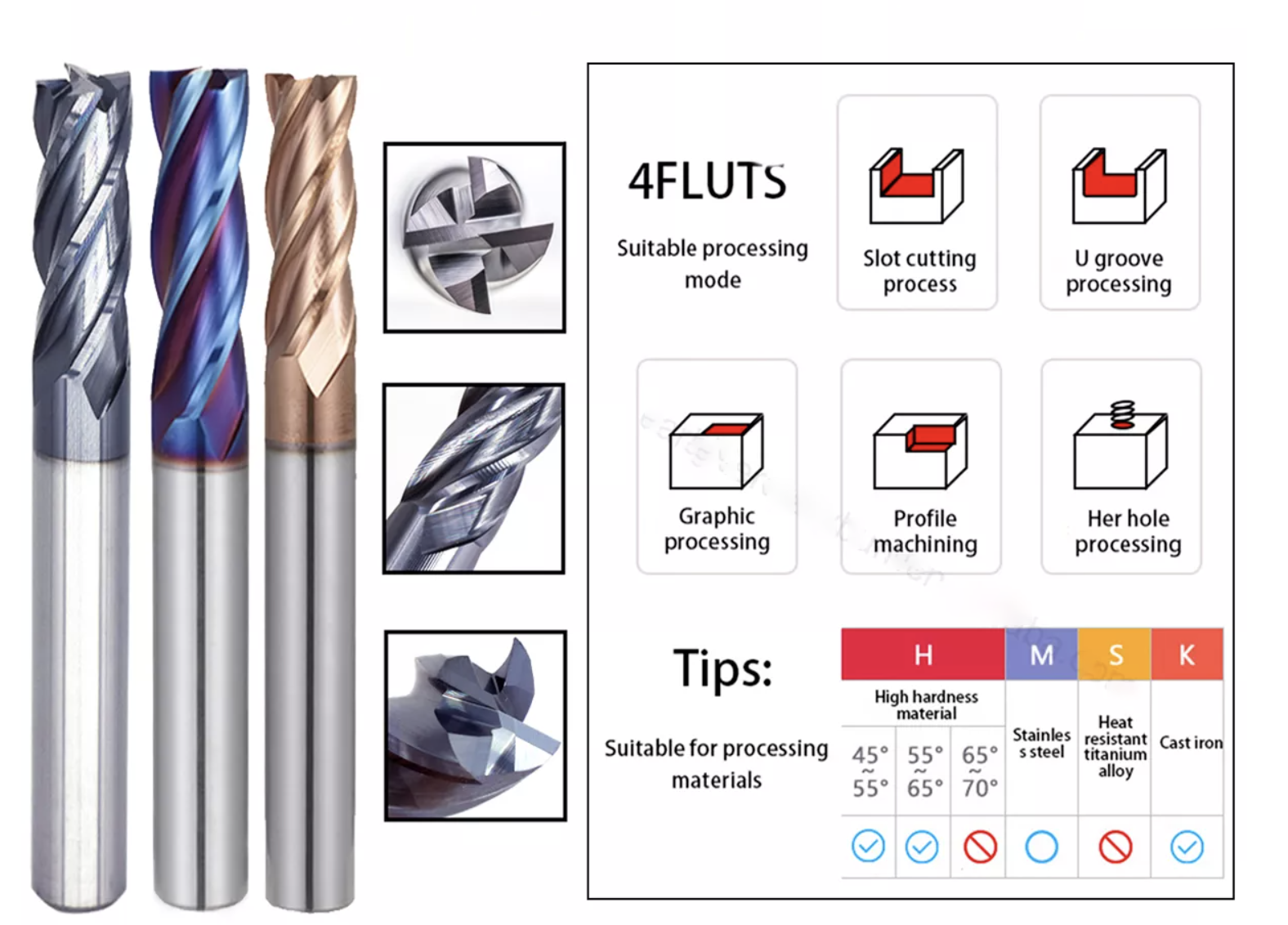

I-Solid Carbide Fresa Diamond Coating CNC 4 Flutes Square End Mill Cutters

I-Specificatoin enemininingwane

Lezi zisikwe ze-Kedel zigcina izinqamu ezine ze-carbide end milling cutters zine-engeli ye-helix engu-30 futhi ziyi-central cut for plung, slotting kanye nephrofayili. Njengawo wonke amathuluzi ethu aqinile e-carbide, lezi zigayo zokuphela kwe-stub zikhiqizwa kusetshenziswa imishini yesimanje, izinqubo zokukhiqiza kanye namasu okuhlola, okuwenza abe yinketho ekhethwayo yama-endmill e-carbide kochwepheshe bemishini abafuna ukukhiqiza izingxenye zekhwalithi ephezulu ezinempilo ephezulu yamathuluzi. Ukwengezwa kocwecwe lwethu lwe-ALTiN kuvumela isivinini esithe xaxa & okuphakelayo kanye nempilo ende yamathuluzi.

1. Ivumela ngokugcwele ukugijima kumapharamitha wokwenza imishini, okuholela kukhwalithi yokuqeda.

2. Ukusebenza okuhle kakhulu ekwenzeni i-titanium, insimbi engagqwali kanye nama-alloys okushisa aphezulu.

3. I-coating ihlinzeka ngempilo ende yamathuluzi noma amanani akhuphukayo wokusika.

4. Ifanele zonke izinhlobo zensimbi noma zensimbi.

I-Premium Sub-Micrograin Solid Carbide End Mill

4 Umtshingo

Isikwele End

Isiphetho Sisodwa

30 ° Helix

I-Stub Length End Mills

Centre Cutting Carbide Endmill

I-ALTiN Yenzelwe Ukusebenza Okunyukile Nempilo Yamathuluzi

Kwenziwe eshayina

I-ALTIN Coating: Ukusebenza okuphezulu kokunamathela kwezinsimbi ezingenasici, izinsimbi ze-carbon, izinsimbi ze-alloy, ne-cast iron. Lokhu kunamathela kumelana nokushisa kakhulu futhi kungasetshenziswa ngokupholisa noma ngaphandle kwaso. Kuyinto ehlukile okunzima ukwenza imishini lapho ukunamathela okunamathelayo kuphezulu kakhulu.

Isicelo

1. NgeCopper, Cast Iron, Carbon steel, Tool steel, Mold steel, Die steel, Stainless steel, Plastic, Arcylic, njll.

2. I-aerospace, ezokuthutha, okokusebenza kwezokwelapha, ukukhiqizwa kwezempi, ukuthuthukiswa kwesikhunta, amathuluzi nensimbi, njll.

Mayelana ne-Coating

| Isingeniso sokumboza | ||||||

| ENDMILL IBANGA | Igama Lokumboza | Umbala | Hv | μm | Ukungqubuzana | I-Max ℃ |

| I-HRC45 enamathela | I-AlTiN | mnyama | 3300 | 1--4 | 0.7 | 850℃ |

| I-HRC55 yokugqoka | TiSiAlN | eyethusi | 3400 | 1--4 | 0.7 | 900℃ |

| I-HRC60 enamathela | I-AlCrSiN | mnyama | 4000 | 1--7 | 0.35 | 1100 ℃ |

| I-HRC65 enamathela | i-naCo 3 eluhlaza okwesibhakabhaka | eluhlaza okwesibhakabhaka | 4500 | 1--7 | 0.45 | 1200 ℃ |

| I-Stainless Steel enamathela | i-naCo 3 Gold | igolide | 4500 | 1--7 | 0.55 | 1200 ℃ |

Mayelana Nokusika

Imininingwane Yomkhiqizo